Printers and printing facilities

Located in the SBU Engineering Building and the Composites prototyping Center (CPC)

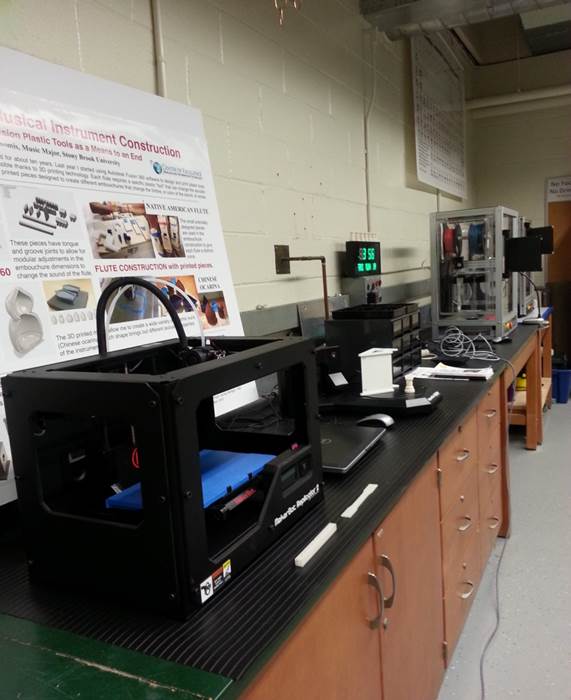

Thermoplastic Polymer Printers

One of the most readily available printing techniques, thermoplastic polymer printers use plastics such as ABS, and PETG filaments to print. Accessible to students either through the department or through open-workspaces such as iCreate and the Innovation Lab, these printers can be used to create plastic prototypes and manufacture AutoCAD designs.

LEARN MORE

UV/Photopolymerization and Digital Light Processing Printing

DLP and photopolymerization techniques for 3D printing are characterized by their use of light to solidify liquid photopolymer resins. While both methods use vat polymerization to create prints, stereolithography (SLA) uses concentrated UV light to create detailed prints from the bottom up. Using digital light processing, DLP printers are able to solidify resin entire layers at a time, creating a faster build.

LEARN MORE

Composite Prototyping Center (CPC) & Design Assistance

Working alongside Stony Brook students and professors, the CPC offers a range of utilities such as full prototype manufacturing, technical training on materials manufacturing, state-of-the-art systems and critical testing capabilities.

LEARN MORE

Design Tools

Stony Brook University provides its students with licenses for design tools such as AutoCAD, Fusion 360 and MatLAB. Additionally, students and professors are able to take advantage of Senvol Additive Manufacturing Database.